Complex systems, evolution and the management of manufacturing change

Christen Rose-Anderssen, James Baldwin, and Keith Ridgway

University of Sheffield

ABSTRACT

The aim of this paper is to provide a natural framework for the management of manufacturing change. The framework is designed, firstly, by describing the characteristics of dissipative structures. This is expanded upon by presenting the essentials of complex systems in way of evolution. Darwinian evolution and change is then discussed from a perspective of complex systems. The classification instruments of change are explained in terms of the complex system and evolutionary perspectives. Then the application of the classification instruments are demonstrated through a case of discrete manufacturing systems.

Introduction

The paper sets off by discussing change through the overall perspective of complex systems science. The main difficulty about complex systems is to see and understand the total make-up of all its related parts. What about all the important small and almost hidden parts that may be significant? What do different person see? C. Rose-Anderssen in 1994 made the painting below and named it Complexity (see Figure 1). People see different things in it. Something in it is partly hidden. And so is our complex world. Similarly, the paper tries to show how the complexity of a reality can be made comprehensive through classifications and the communication of this reality.

Figure 1

Today's reality for manufacturing companies requires a strategy with a strong emphasis on creativity, innovation and, therefore, ability to change. Rose-Anderssen et al. (2005) argue that complex systems science concerns the transformation and evolution of systems over time, and, may therefore, provide a natural overall framework for managing change in manufacturing organizations. The paper sets off by discussing changes through the overall perspective of dissipative structures, complex systems and evolution. This is followed by a description of Darwinian evolution and change. The application of complex systems in manufacturing is explained through Linnaean and cladistics classification. Finally, the management of manufacturing change is demonstrated through these applications.

Dissipative structures

The Nobel laurate Ilya Prigogine (1978) argued that the non-existence of time in physics and chemistry is closely related to the Second Law of Thermodynamics. The Second Law of Thermodynamics is categorical in its statement that ‘it is impossible for any engine cycle to transform all of the heat supplied to it into work (Lockey, 1966). This deficiency can only be met by a suitable defining variable, namely entropy so that the function of the absolute temperature, T, in terms of the total entropy is equal to the heat supplied during an internally reversible heating process (Lockey, 1966). Clausius paraphrased the statement: ‘Heat will not continuously flow from one body to another body without requiring the input of energy from the surroundings’ (Lockey, 1966). In practice the entropy for a closed thermodynamic system is a quantitative measurement of the amount of thermal energy not available to work.

A reversible process is defined as one which can be exactly reversed and the system returned to its original condition after passing through the same states on its return journey, and after exchanging the same amount of heat and work with its surroundings (Lockey, 1966).

Prigogine in his Nobel Lecture (1978) says that it is a remarkable fact that the Second Law of Thermodynamics has played in the history of science, a fundamental role far beyond its original scope. The problem of time in physics and chemistry being closely related to the formulation of the Second Law. He argues (1978) that the more we know about the universe the more difficult it becomes to believe in determinism. According to Prigogine determinism loses its explanatory power in the face of irreversibility and instability. As he explains determinism is fundamentally a denial of the arrow of time. From that perspective it means there is no longer a past, a present and a future. He maintains that there are examples of irreversibility including diffusion, radioactive decay, solar radiation, weather and the emergence and evolution of life.

Prigogine (1978) distinguishes between two types of structure; equilibrium structures, which can exist as isolated systems, and dissipative structures, which can only exist in symbiosis with their surroundings. Dissipative structures may display two types of behavior. When close to equilibrium their order tends to be destroyed whilst far from equilibrium order can be maintained and new structure be formed. Prigogine (1978) defined dissipative structures as physical and chemical systems far from equilibrium conditions. They tend to develop ‘order out of chaos’ and are self-organizing. Matter and energy (of low entropy) flows through the structure. Primarily the energy and negative entropy is dissipated. Exactly as in the cases of the mean field theory breaks down near instability, new dissipative structures originate. Her fluctuations play an essential role.

In an isolated system, which cannot exchange energy and matter (Prigogine et al, 1972) with the surroundings, this is expressed in terms of a function of the macroscopic state of the system, and that is entropy. Prigogine (1978) says that, since the beginning of the last century we have been prepared to find new theoretical structures in the micro world at the elementary particles or in the macro world of cosmological dimensions.

| Dissipative structures | |

|---|---|

| Structures | Characteristics |

| Irreversibility | There is past, present and future |

| Determinism | Loses the explanation of irreversibility |

| Macroscopic | World of cosmological dimension |

| Microscopic | World of elementary particles |

| Dissipative structures | System is far from equilibrium |

| Fluctuations | Essential in creating instability |

| Self-organization | Order through fluctuations |

Table 1: Dissipative structures

Complex systems and evolution

Peter M. Allen, a colleague of Prigogine for 20 years, through his simulation models has researched into a broad field of dynamical systems. The fact that irreversibility is a feature of the real world being established, the expansion of complex systems science can be discussed.

Macroscopic versus microscopic

Allen (1997) describes the micro as the internal detail of an element in consideration. The macro concerns the more global level, whilst the meso is about the system in consideration. He argues that the system (meso) will be changed according to the mechanisms which are affected by the external environment and the internal (micro) nature of the elements involved.

Dissipative structures

Dissipative structures can be described as examples where the molecules underlying the chemical and biological reactions do not change their structure. They cannot learn by the interactions they are subject to.

Self-organization

In general, self-organization can be seen as the adaptive response to changing external conditions (Allen, 1997). That is self-organization is a collective response to changing conditions. This deterministic and mechanical behavior can be characterized by two assumptions according to Allen (1997):

- Events occur at their average rate.

- All individuals of a given type are identical and of an average type.

Evolution

There is a distinction between self-organization and evolution. The essential characteristic of self-organization is by assumption 2 that all individuals are identical and equal to the average type. Evolution, however, which is a main feature of the real world is characterized by diversity. There microscopic diversity characterize the variables at any particular time. In result, the outcome can be presented as an evolutionary tree, where new behaviors emerge. This will produce a co-evolutionary interaction between the system and the environment (Allen, 1997).

Allen et al. (2006) argue that the underlying mechanism of evolution involve micro-diversity within a system, and how this drives an evolving, emerging system structure that is characterized by a changing level of structural diversity.

Complex systems

Allen (2001) argues that it is the explorative behavior within a system that is essential in order for the system to adapt, change and evolve in response to whatever selective forces are placed on the system by the environment. Hannan and Freeman (1977) maintains that the literature mainly emphasizes organizational adaptation. Like Allen (2001) they make a clear link between adaptation and selection. Their argument is that it is the environment that optimizes by selecting optimal combinations of organizations. Selection is therefore owing to fitness. In other words, they argue that a given form of organization would sustain in a certain environment.

Allen (1997) argues that a complex system is one where there are many sub-systems connected together. For systems made up of micro-components with fixed internal structure, their interactions can lead to self-organization. However, if the micro-components have internal structure, and if in addition this can change through time, thus changing the behavior of the individual elements, then evolution can take place as the emergent macro-structure affects the local circumstances experiences by individuals. Such systems that are open to exchange of energy and matter with their external world corresponding to a decrease in entropy to a self-organizing one.

These self-organizing systems will have two modes of change (Allen, 1997). At one stage which is deterministic towards what happens to the variables of the system. Fluctuations, although present, may be unable to de-stabilize the system. At another stage, chance is involved as it concerns the behavior of the system near instability. Fluctuations may then drive the system away from its present stable position. It is, thus, the chance at the critical moment that makes the system unstable. This is, thus, an interplay of chance and necessity.

Intervening in a system and triggering an instability in order to create a coherent fluctuation will be an energetic cost related to its size. Without such an intervention, the precise moment and path of an instability depends on the detail of the fluctuations that are occurring, which will be unpredictable.

Allen (1997) argues that in order to understand the self-organization and change one also have to consider stability and resilience. Resilience refers to the ability of the system to stay within its basis of attraction and resist being kicked over into another basin, and another pattern of behavior. Structural attractors being the set of interacting factors that have mutually supportive, complementary attributes. They express the natural synergies and conflict of underlying systems (Allen, 2001). In real time, a system is driven through successive instability by fluctuations. In that sense both the structure and fluctuations around that structure are the result of the evolutionary process. The adaptability and resilience that result are natural properties of complex systems.

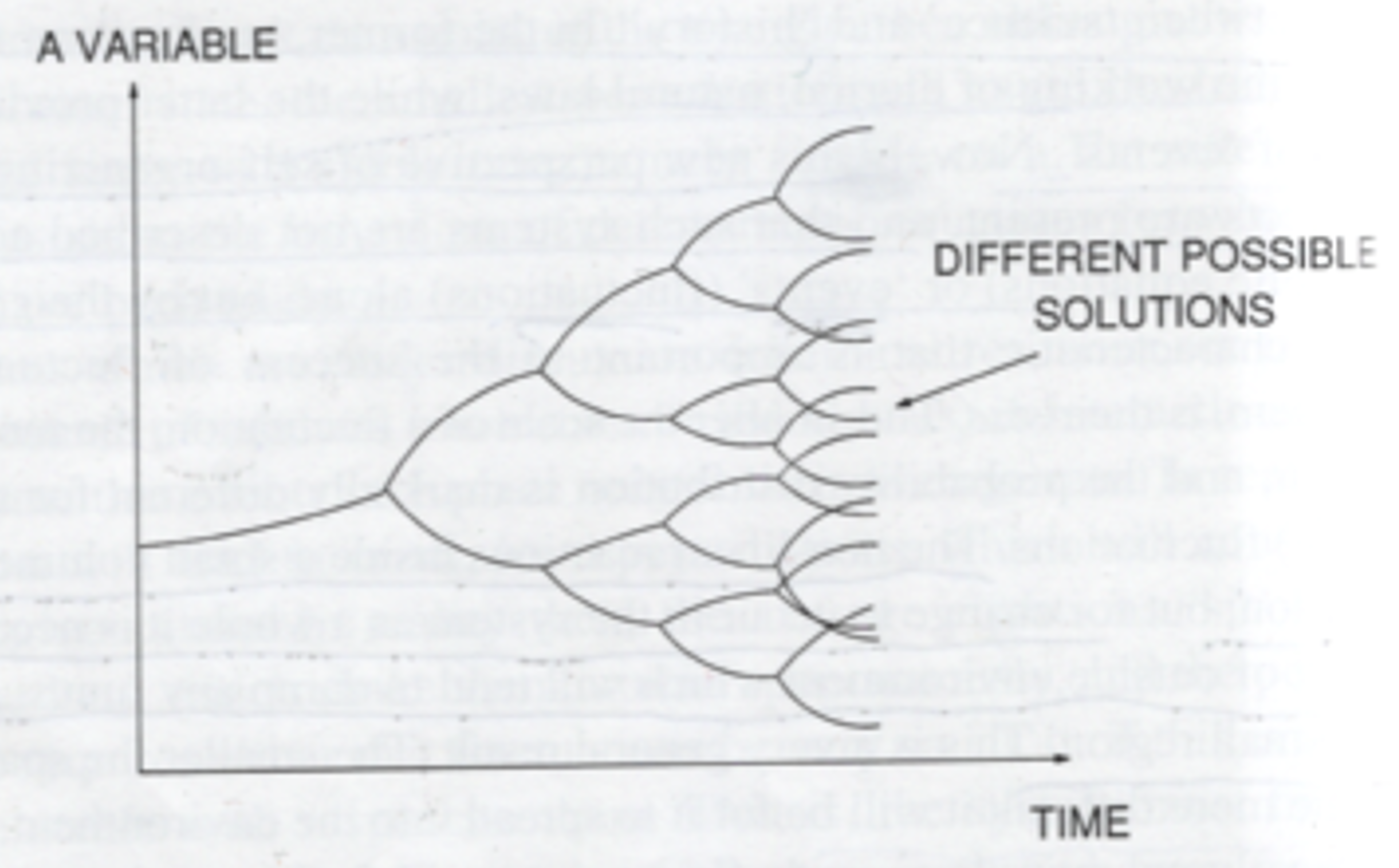

With non-linear interaction between the micro-elements this can give rise to macroscopic states of organization and behavior that undergo bifurcations (see Figure 2). That is, for identical external conditions, various possible structure can exist. Each of them which is perfectly compatible with the microscopic interactions (Allen, 1997). Such a system can evolve from a relatively simple initial state of organization, through successive instabilities to a very complex pattern of structure and flows (Allen, 1997).

Figure 2

When the system is near to a ‘branching’ or ‘bifurcation point it is relatively unstable. Therefore small, chance disturbances, which are always present in the system can be decisive in nudging it onto another branch rather than another.

In self-organizing systems, the timing of events, and of successive instabilities play a vital role in the evolution of the system and the emergent structure. The same fluctuation at a different time, or context, will produce different result (Allen, 1997).

The models of self-organization and evolution are telling us that not only is classification an essential part of the problem of understanding, but, through time, the relevant classification will change and the variables and their attendant equations will change in different phases of the system (Allen, 1997).

| Complex systems and evolution | |

|---|---|

| System Characteristics | Evolutionary outcome |

| • Micro-component with fixed internal structure | • Interaction may lead to self-organization |

| • Resilience | • Ability of system to stay within its attractor basin |

| • Micro-component with changeable internal structure◦ Micro-diversity | • Evolution may take place◦ May evolve from small initial state |

| • A system is driven through successive instability | • Structure and fluctuations are result of evolutionary process |

| • A system near a ‘branching’ point | • Small, chance disturbance can be decisive in nudging system on to a different branch |

| • Intervention into a system to trigger instability | • Creating coherent fluctuation for more predictable results |

Table 2: Complex systems and evolution

Darwinian evolution and change

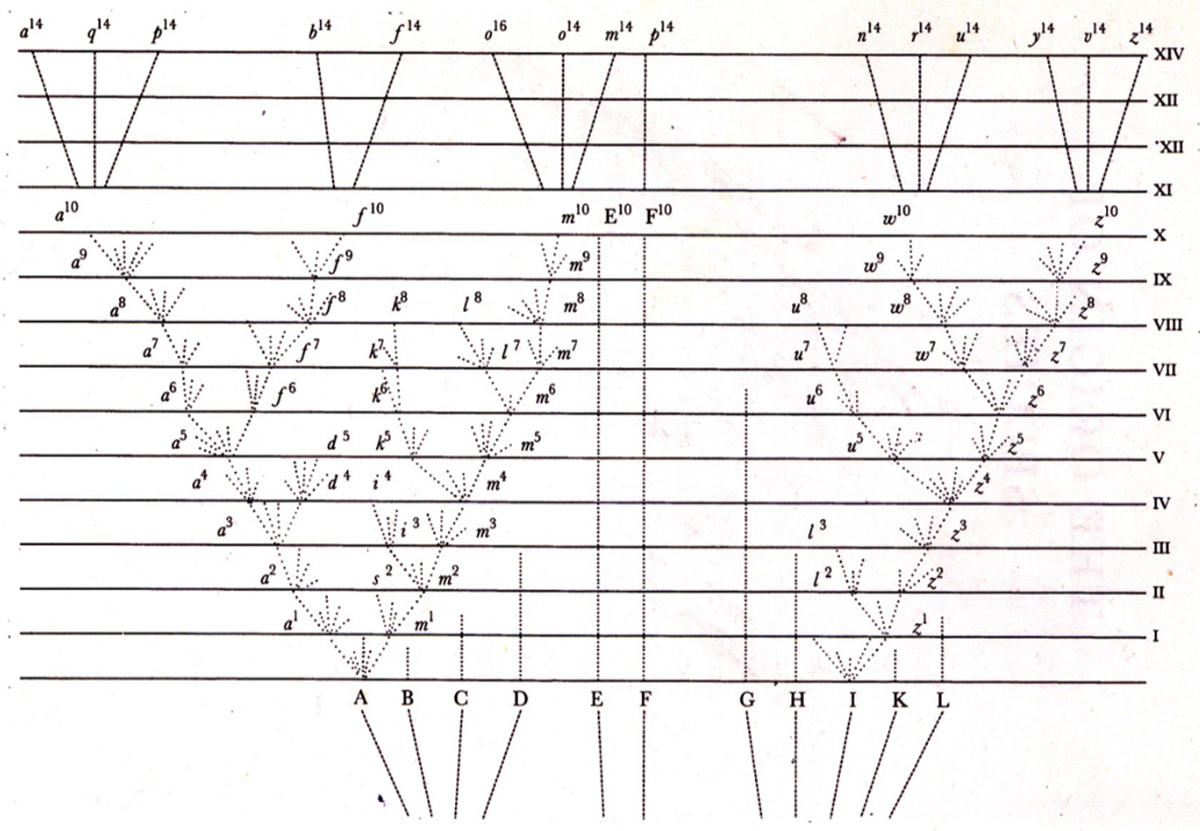

In his classification, Darwin (1859) uses a tree of life to explain the evolutionary history of biological Species. The Darwinian approach is about the long-term evolution of Species through variation. These variations are small but significant and result in irreversible changes to a Species. Darwin (1859) argues that Species are not completely unique, but they share morphological similarities. Species can therefore, he suggests, be classified into a pedigree or evolutionary tree based on the similarities between them (see Figure 3).

Figure 3

In his evolutionary tree (Figure 3), Darwin (1859) basically illustrates how Species A after a thousand generations has produced two fairly well marked Varieties a1 and m1. They are slightly modified forms of their parent generation. And they have inherited those advantages that made their parent generation more successful than their competing Varieties. In his tree, Darwin (1859) shows the evolution of Varieties a1 to a2, and m1 to m2 etc., selected by nature through producing advantageous variations that make them sustain. Darwin (1859) argues that it is never straightforward to ascertain whether two forms should be defined as different Varieties of a Species or simply be ranked as two different Species. More specifically, the degree of difference between Varieties is much less than the difference between Species of the same Genus (hierarchical level above Species). The principle of divergence of character (Darwin, 1859) happens in the long-term, in thousands of generations, as Varieties become more distinct from each other. From an evolutionary perspective, Darwin (1859) argues that Varieties are actually Species in the process of formation. The split between Varieties is a major bifurcation of evolution leading to a new Species. Rose-Anderssen et al. (2016) tried to answer how manufacturers can make sense of variety and see opportunities for the future.

Micro-component with fixed internal structure

A Species can thus for a thousand generations have a fixed internal genetic structure. In that respect the Species has been well adapted to its environment, and therefore retained its genetic structure.

Resilience

The resilience of a Species is about the ability to stay within its basin of attraction or traditional environment. Natural mutations are rare events and when they occur they almost always produce injurious characteristics (Uvarov et al, 1964). However, it is due to the natural selection of strains of organisms which have become better adapted to their environment, as a consequence of genetic mutation, that the evolution of Species has taken place. More favourable varieties are retained within its environment.

Micro-component with changeable internal structure

Genetically, the micro-diversity that drives the evolution of a Species occurs through mutations. A mutation being a change in the chemical constitution of the chromosomes of an organism (Uvarov et al., 1964). Nature favors a mutation that increases the fitness in its environment, and it culls mutations that decreases the fitness of the individual. In this way nature through Natural Selection is trying to economize in every part of its organization of Species (Darwin, 1859). The successful genes are those that have beneficial effects on the adult and are likely to reproduce the same genes on to future generations (Dawkins, 1989).

For Darwin (1859) Natural Selection is about the preservation of favorable variations and rejection of injurious variations. In nature there is a competition between the spread of sustainable Varieties over different environmental challenges between members of the same Species and Species of the same Genus (see Figure 6), because they frequent the same habitat for the same food (Darwin, 1859) and using the same performance characteristics. Therefore, variability is important for the evolution and the sustainability of a Species. Thus, this is about the Species and Species Variety that fits best into a particular environment. It is not necessarily about the strongest but rather about Species, Species Variety and Individual that overall fits in.

The environment is tough and demanding. Darwin (1959) observed that a species during its lifetime is constantly suffering from enemies and competitors occupying the same place and searching for the same food. The enemy or competitor having only a slight favorable characteristic fitting a slight change in the environment will prevail. The less favorable species will decrease in number. This is the principle of survival of the fittest.

A system is driven through successive instability

In his evolutionary tree (Figure 3), Darwin (1859) illustrates how Species through successive instability to its genes have resulted in irreversible changes to Species. The less successful Varieties becoming extinct and ending up as dead branches on the tree (see k8, l8, etc.). The successful Species having inherited the advantages that made their parent generation more favorable than their competing Varieties.

A system near a ‘branching’ point

Darwin (1859) argues that the principle of divergence of character happens in the long-term, in thousands of generations, as Varieties become more distinct from each other. From an evolutionary perspective, he argues that Varieties are actually Species in the process of formation. The split between Varieties is a major bifurcation of the evolution leading to a new Species. As Darwin (1859) shows in way of his evolutionary tree after many generations slightly modified forms or Varieties of the Species may be produced. The bifurcation point at the Species A resulting in the two Varieties a1 and m1is such a case. The internal genetic structure is here changeable.

Intervention into a system to trigger instability

Human intervention into the Natural Selection by nature is discussed extensively by Darwin (1859) under the chapter Variation under Domestication. The idea behind this is to achieve a more rapid change and select for different characteristics than nature would have done. Belgaev (1979) argues that varieties or sub-varieties of cultivated or domesticated plans or animals differ more from each other than do individual of any Species or Variety in nature. And this is because they have been subject to more varied selection criteria than nature has made available. He further argues that this high degree of Variability is favorable as it gives nature more freedom to select from.

| Darwinian evolution and change | |

|---|---|

| Complex systems characteristics | Evolutionary outcome |

| • Resilience | • More favourable variety is retained within the environment |

| • Micro-component with changeable internal structure | • A slight favourable variety may fit a slight change in the environment best |

| • A system is driven through successive instability | • Successive instability results in irreversible changes to a species |

| • A system near a ‘branching point' | • A major bifurcation point leads to a new species |

| • Intervention into a system to trigger instability | • High degree of variability gives nature more freedom to select from |

Table 3 : Darwinian evolution and change

Linnaean and Cladistic classifications as instruments for applying evolutionary complex systems to real-time change

The paper is concerned about how the complexity of a reality can be made comprehensive through classification and the communication of that reality. In this section, complex systems and evolution, plus Darwinian evolution and change is explained through Linnaean and cladistics evolution.

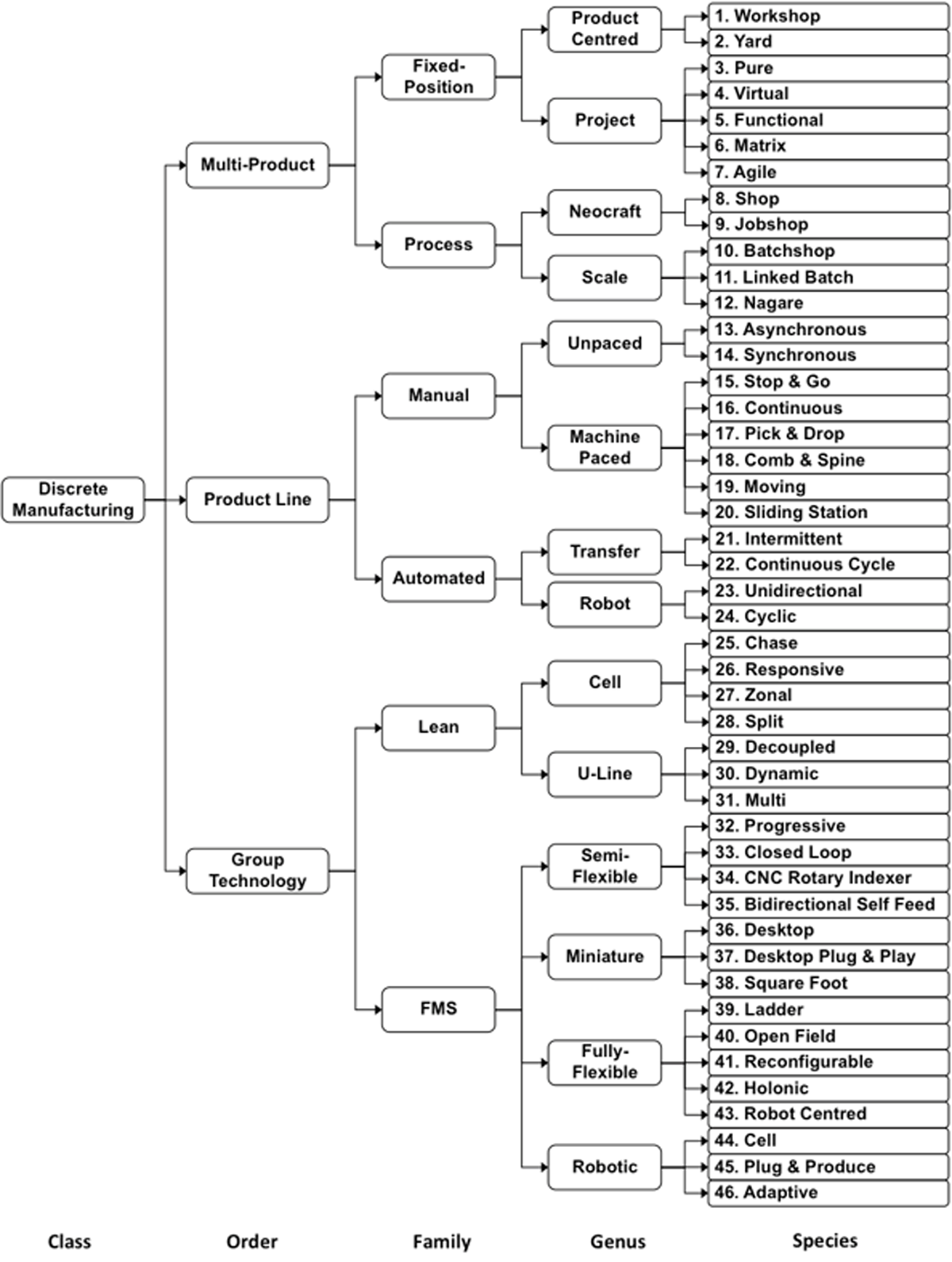

A classification is meant to provide a simple and generalized but authoritative representative of complex phenomena and is the basis for communication and understanding (McCarthy, 2005). Haas and Johnson, (1966) argued that classifications help refine hypothesis, determine validity and utility based on logical and intuitive reasoning, provide a basis for prediction, and specify populations from which samples could be drawn. Classification is both a process (i.e., classifying) and a product (i.e., classification). Taxonomy, which in ancient Greek means method (-nomia) of arrangement (taxa), is the science of grouping and naming of phenomena on the basis of similarity or shared characteristics. The most notable pioneer in formal taxonomy was Linnaeus (1958), who introduced a system of biological classification, arranged in a hierarchy of kingdom, class, order, genus, and variety (see Figure 6).

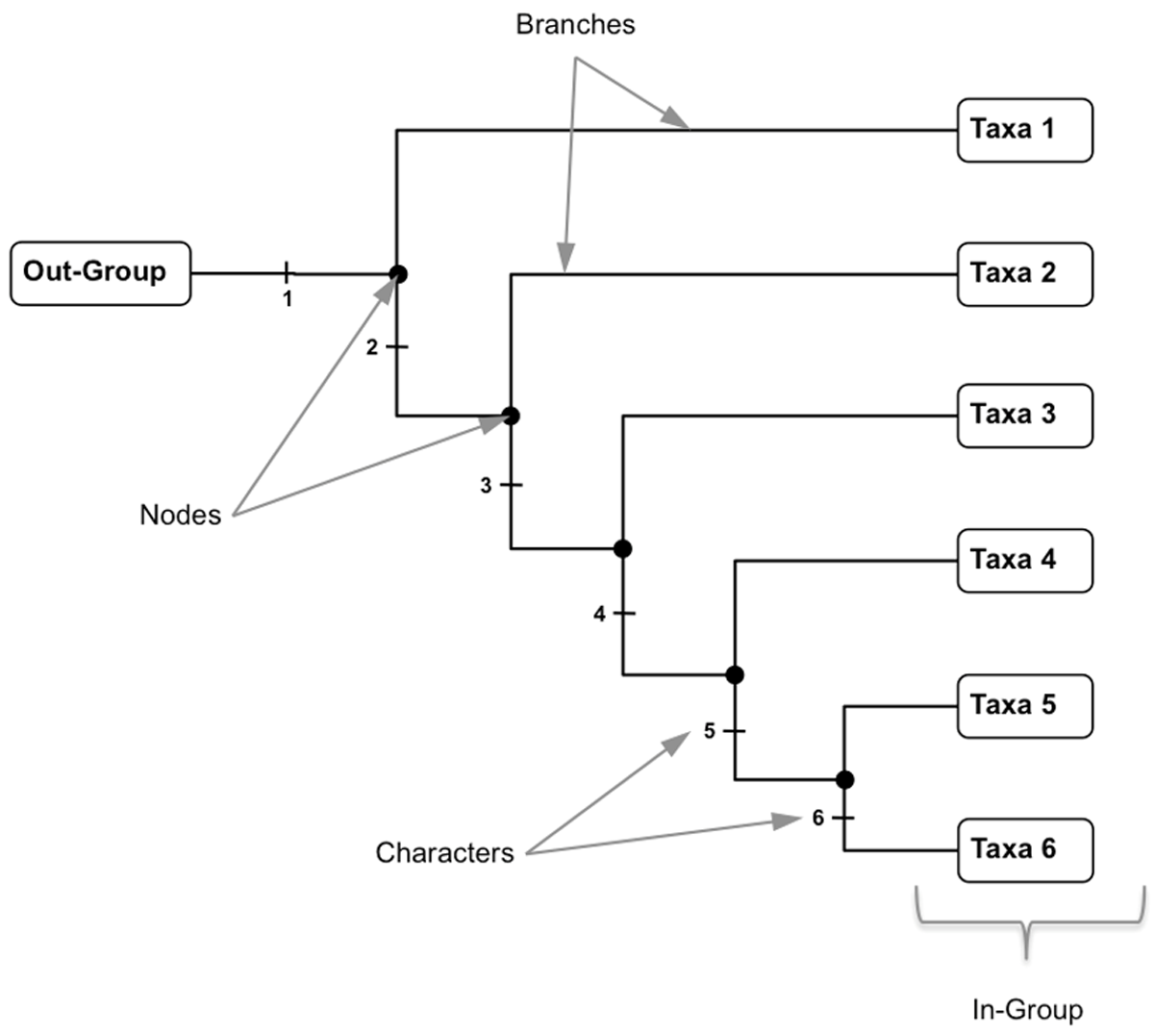

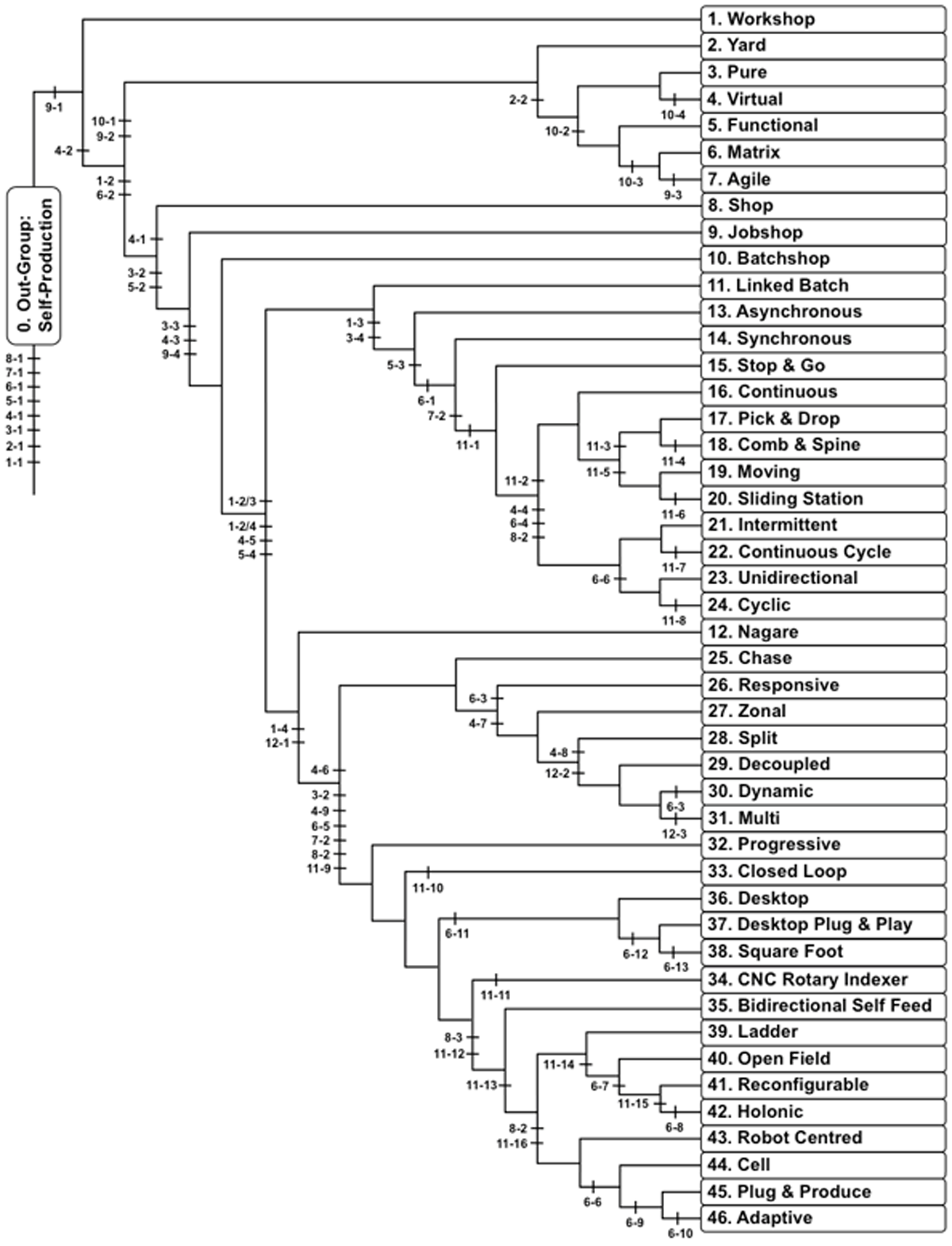

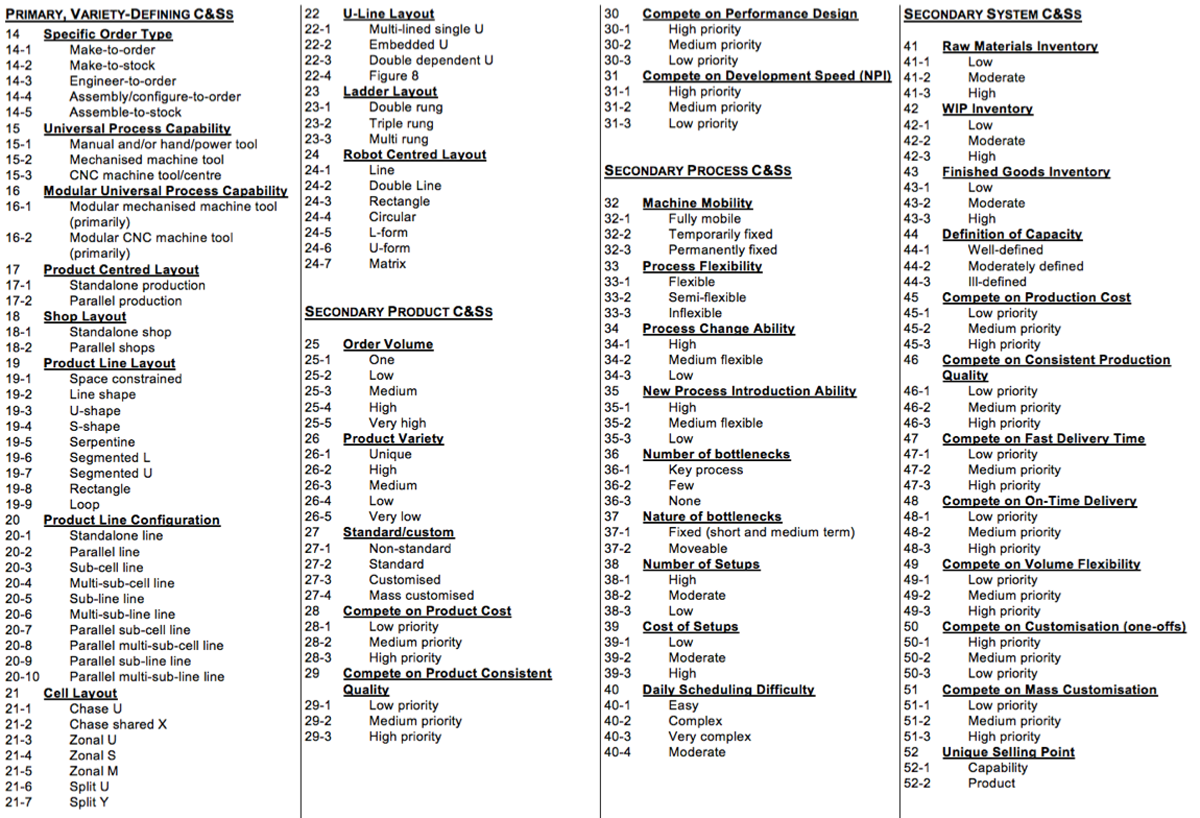

Cladistics is a purist approach, based entirely on ancestor-descent relationships (Hennig, 1966), and where physical similarity is consequential. The outcome of a cladistics analysis is a cladogram (see Figure 4 below), a branch and node diagram (from ancient Greek: klados—“branch”). Data, in the form of characters and states are typically drawn from surviving taxa. This approach investigates the evolutionary links between taxa, through characters and states, and studies common ancestors.

Figure 4

Numbering characters, helps with both ordering and decisions concerning whether they exist in the forms of organization under study (Leseure, 2000). This is a trial and error process where characters are continuously compared, recoded and/or rejected. Different states for each character are proposed and an indication given of what species possess which state. When this cannot be developed any further, a saturation of categories has been reached. The character itself is shown in the list of characters relevant to the clade. Each character is then shown with its primitive (1) and derived (2, 3…n) states. It is important to note here that states are numbered in this study according to their estimated appearance in the evolutionary scheme and have both an additive and discontinuous nature. With discontinuous state evolution, one state does not necessarily follow, in evolutionary terms, the one numbered before. That is, the states within characters also follow a similar evolutionary pattern and can branch off as shown with the character in Figure 5 below. In this example, evolution diverges at state 2 leading down one path to states 3 and 4 and down the other path to states 5 and 6. A change in character state signifies an evolutionary step.

Figure 5

In line with the Darwinian section of the paper, from here on the manufacturing systems discussed are separate Species which relationship are presented in cladistics and Linnaean-hierarchical classifications.

Micro-component with fixed internal structure

In terms of fixed or limited internal structure, the Out-Group (see Figure 4) or more ancient Species in the cladogram is a relevant representation thereof. It is simple and that does not make it flexible enough to be applicable under a great variety of circumstances. However, after a long time it has succeeded in giving offspring in a different environment. It thereby represents the shared ancestor of all the related Species considered in the cladogram.

Resilience

Species which fit well into their environment are resilient to change. However, the resilience of a species in real time is a temporary one as the instability caused by the environment will drive it to change.

Micro-components with changeable internal structure

Species with several Variety options are more adaptable in an eventually changing environment. Also, a Species that needs to change only a few character states is more realistic to sustain in a changing environment.

At the Nodes or bifurcation points a new character occurs. In Figure 4, Taxa 2 emerges as Character 2 is introduced. Taxa 2 shares character 1 with Taxa 1. Taxa 3 emerges as character 3 is introduced. Taxa 3 shares character 1 and 2 with Taxa 2. In the figure Taxa 1 to 6 represent the In-Group that is the taxa under investigation.

A system driven through successive instability

A cladogram will reveal how Species have evolved through transforming certain character states.

Figure 4 shows how new species (taxa) have evolved due to the Species having been driven through successive instability. It is when a variety (mutant) has successfully retained over time that a new species has been established. This is the generalized ‘Darwinian’ principle of variation, selection and retention.

A system near a “branching” point

A Species that is easy/cheap for users to change due to small character state changes is near a “branching” point. That is when a variety of a species (taxa) in Figure 4 has been successfully retained it is established as a species. For example (see Figure 5), when character state 1-2 at first occurs it produces a variety to the species where character state 1-1 has been dominant.

Intervention into a system to trigger instability

Human intervention into classifications systems could trigger some instability by changing few or several character states.

This could mean introducing new characters and states into an obsolescent species.

| Linnaean and cladistics classifications as instruments for applying evolving complex systems to real-time change | |

|---|---|

| Complex systems characteristics | Application to real-time change |

| • Micro-component with fixed internal structure | • The out-group has a limited internal structure |

| • Resilience | • The resilience of a species in real-time is temporarily |

| • Micro-component with changeable internal structure | • A species needs to change only a few character states is realistic in order to sustain in a slowly changing environment |

| • A system driven through successive instability | • When a variety (mutant) has successfully retained over time it has become a new species |

| • A system near a branching point | • At a branching point small character state changes may produce a new species |

| • Intervention into a system to trigger instability | • Human intervention could trigger instability by changing character states |

Table 4: Linnaean and cladistics classification as instruments for applying evolutionary complex systems to real-time change

The management of manufacturing change through classification

In this section, complex systems, evolution and the management of manufacturing change is demonstrated through Linnaean and cladistics classification. Rose-Anderssen et al. (2017), in detail, showed how cladistics and hierarchical classification can be applied as tools for manufacturing development and change.

Allen et al. (2006) used the ideas of evolutionary drive when looking at the cladistics classification of the automobile manufacturing forms. In this paper the ideas of evolutionary drive consider the cladistics and Linnaean classifications of the whole sector of discrete manufacturing systems. Taxonomy and classifications have been useful tools in managing the information on living entities, their genetics, form and behavior. The system of hierarchical biological classification was originally described by Carl Linnaeus in his book, Systema Naturea written in 1735 (Linnaeus, 1958). Here he describes systematics as the scientific inquiry into biological differences. The group into which organisms are placed are referred to as taxa (singular: taxon). The taxa are arranged in a hierarchy. He grouped according to shared physical characteristics. In Systema Naturea he divided nature into three Kingdoms: Mineral, Vegetable and Animal. His biological classification was limited to Kingdom, Class, Order, Genus, and Variety. The taxa are arranged in a hierarchy. This ranking has later been added to and adjusted in order to be more consistent with the Darwinian principle of common decent. This paper keeps to the ranks of Class, Order, Family, Genus and Species. Within a Species there may be several Varieties.

The Linnaean hierarchy, however, has its disadvantages as it ranks groups of organisms artificially into a hierarchy. Still, by combining these two classifications, hierarchical and cladistics, a more comprehensive classification of a complex phenomenon is ensured. In the Linnaean hierarchy, the level above connects a group of Species. This connecting point is the Genus of this group of Species. The characters shared by these Species are held by the Genus. The level above that connects that group of Species to similar groups of Species. The connecting point is the Family all these Species belong to. In that way more and more Species belonging to the discrete manufacturing sector investigated are connected. Thus the Linnaean hierarchy becomes extremely useful in the process of constructing a phylogenetic tree of the phenomenon (discrete manufacturing sector) that is large and very complex. It is an iterative process where the cladistics informs the Linnaean hierarchy and vice versa. Therefore several “generations” of mutual phylogenetic and Linnaean classifications would be developed.

Figure 6

The classification systems applied in the paper gives meaning to the characteristics of discrete manufacturing systems. The conceptual applications, the ideas or mental pictures, applied are grouped within the cladistics and Linnaean relationships. Cladistics is about evolutionary relationships between entities. Thus cladistics is really an approach to classify which items are grouped together based on whether or not they have one or more shared unique characteristics that come from the group's common ancestor and are not present in more distant ancestors. Therefore, members of the same group that are thought to share a common history are considered to be more closely related. Change in characteristics occurs over time. It is only when characteristics change that we are able to recognize different lineages or groups. The outcome of a cladistics analysis is a cladogram, a tree shaped diagram that represents a phylogenetic hypothesis on evolutionary relationships.

Micro-component with fixed internal structure: The ancient manufacturing—Out-Group

The evolution of the manufacturing species in pre-historic or ancient times is about a journey of adaptation to an ever but slowly changing environment. The characteristics of the species remained fixed for thousands of years. They could sustain in remote areas with small populations, with little internal competition, where there were no influence of matter and energy from the outside. As such, the out-group has a limited internal structure.

The journey of the ancient manufacturing man runs through the different Stone Age periods, and from there to the Bronze Age and Iron Age. During the Mesolithic period (10,000-6,000 years ago) he makes simple stone tools for himself. He is not highly skilled. There is no orientation towards a market, there is no variation, and man uses a simple stone to make his tool. He is working alone. He makes his single product on his lap, i.e., the general layout character is fixed position. He performs his work on site in the protection of his dwellings, his covered dedicated facility. He uses his hands in a single universal process of producing his tools. He performs all the processes of producing his tools. The job is done in one go with no buffer between processes. He uses a stone as his manual hand tool to hammer / chisel out his new tool. He picks up and carries the material he is going to work on back to his dwellings. This is his important primary material handling. He moves the raw stone piece around in his hand while he is working on it. This is his secondary material handling. Based on these findings, the following Out-Group characters are suggested:

- 1-1 Fixed position layout;

- 2-1 On-site (dedicated facility);

- 3-1 Single universal process type;

- 4-1 Performs all processes; produces full product;

- 5-1 No buffer between processes;

- 6-1 Manual / hand-tool;

- 7-1 Manual / mechanized primary material handling system;

- 8-1 Manual / mechanized secondary material handling system;

Resilience

The temporary resilience of a manufacturing species lasts as long as it fits the challenges / demands of its environment. The first evolutionary step beyond Self-Production is the Product Centered Workshop (see Figure 7). It came about through the additional CSs 9-1 Entrepreneurial (see Table 5 and Figure 7). This is the most widely spread manufacturing species through history, and even exists today where there is no challenge for change.

Micro-component with changeable internal structure: The challenge of matter and energy from outside

With increasing populations and interactions between communities old systems were challenged.

| 1 General Layout Approach 1-1 Fixed-position layout 1-2 Process layout 1-3 Product layout 1-4 Group technology layout |

8 Secondary Material Handling 8-1 Manual / mechanized 8-2 Combined with PMHS 8-3 Automated |

| 2 Location of Production 2-1 On-site (dedicated facility) 2-2 Remote location |

9 Management style 9-1 Entrepreneural 9-2 Project manager 9-3 Agile project managed 9-4 Centralized |

| 3 General Machine/Process Configuration 3-1 Single universal-machine/process types 3-2 Limited universal-machine/process duplication 3-3 Extensive universal-machine/process duplication 3-4 Single dedicated-machine/process types |

10 PM Resources Power 10-1 Intra-organizational project resource pool 10-2 Functional manager is project manager 10-3 PM has power over specific functional resource secondment 10-4 Inter-organizational project resource pool |

| 4 Operator Task Type / Responsibility 4-1 Performs all processes; produces full product 4-2 Performs significant processes; produces part of product 4-3 Performs single or a very limited set of processes 4-4 Oversees/monitors processes 4-5 Performs all product family processes 4-6 One operator performing all cell processes 4-7 Two or more operators sharing cell processes in zones 4-8 Three or more operators processing a part each which are then brought together for final processing or assembly 4-9 Programmes and oversees/monitors processes |

11 Automated PMHS Type 11-1 Intermittent: Conveyor, in-line, etc., stops for every process/workstation 11-2 Continuous: The operator performs process(es) whilst in motion 11-3 Continuous: The operator removes part/product from the conveyor to perform process(es) then returns it 11-4 Continuous: The operator removes part/product from the conveyor to perform process(es) then feeds it to another conveyor 11-5 Continuous: The operator performs process(es) by ‘walking/moving’ with the in-line cart 11-6 Continuous: The operator performs process(es) by ‘walking/moving’ with the in-line cart; some workstations ‘slide’ past other workstations to perform processes 11-7 Continuous cycle: Parts//products are automatically processed while in motion 11-8 Intermittent cycle: The PMHS cycles 11-9 Intermittent bypass: The PMHS can bypass processes 11-10 Bidirectional: Rotary Indexing PMHS 11-11 Bidirectional: The PMHS can move in two directions 11-12 Mobile: Automated Guided Vehicle (AGV) 11-13 Mobile: Automated Self-Guided Vehicle (SGV) 11-14 Mobile: Artificially intelligent Self-Guided Vehicle (SGV) 11-15 Robot |

| 5 In-process Buffer 5-1 No buffer between processes 5-2 WIP between processes 5-3 In-process buffer seen as waste and removed |

|

| 6 Process Technology Type 6-1 Manual / hand-tool 6-2 Mechanized machines (manually operated machines) 6-3 Modular mechanised machines 6-4 Automated machines (non CNC) 6-5 CNC machine tool 6-6 Robot 6-7 Modular CNC machine tool 6-8 Autonomous CNC machine tool (i.e., with Al) 6-9 Modular robot 6-10 Autonomous robot (i.e., with artificial intelligence) 6-11 Micro machining unit 6-12 Modular micro machining unit |

|

| 7 Primary Material Handling System (PMHS) 7-1 Manual / mechanised PMHS 7-2 Automated PMHS |

12 Cell Buffer 12-1 Decoupling cell buffer (i.e., creating independent cells) 12-2 No buffer between cells (i.e., cells are fully integrated) 12-3 No buffer between lines (i.e., lines are fully integrated) |

Table 5: Primary Species-Defining characters and states

Figure 7

It was therefore needed to question the following; how can manufacturers make sense of variety and opportunities available for change and future survival, secondly, how can these change processes be explained in terms of the complexity of the interconnection of systems, processes and technologies. The paper tries to answer these questions.

The classifications shown in Figure 6, Table 5 and Figure 7 represent the historical evidence given by text-books and confirmed and adjusted through observations in industry. This is the conceptual representation. It represents the change of the internal structure of the micro-components of manufacturing species as they evolved due to challenges / demands of the environment as this changed. As such with the evolution of the manufacturing species this again influenced the environment. In a slowly changing environment a species needs to change only a few character states to sustain.

There is a significant difference in demand that at the order level (see Figure 6) that favors the Class to be split into Multi Product, Product Line and Group Technology.

A system driven through successive instability

The mechanism by which variation can be presented as follows; the gene manipulation alias character state (CS) manipulation. From this point of view successful CSs are those that have beneficial effects on a manufacturing system, and that are likely to be reproduced in future generations of a manufacturing Species. CSs that have been tried out without beneficial effect are ignored in the historical account of Species evolution represented by the cladogram. In the real world these CSs can be said to be formed by accident or by trial and error activities. In that sense there is a competition among CSs that will characterize a manufacturing system. When a variety (mutant) has successfully retained over time it has become a new species.

Figures 6 and 7 illustrate how successive instabilities causes different solutions to evolve for producing new species. These are irreversible changes to the species. The successful species having inherited the advantages that made their parent generation more favorable than their competing varieties in the environment.

A system near a branching point: Small disturbances by new varieties of a species

It is not necessarily the CS that is more advanced or superior that wins but rather the CS that fits best with other CSs of the manufacturing system. This is about the small disturbances that might trigger change. At a branching point small character state changes may produce a new species.

At the next level, a Species of manufacturing is represented by a number of slightly different varieties. Only varieties which endured competition sustains in the historical representation of the Species. Only these may produce new varieties themselves.

Near a branching or bifurcation point, a species is relatively unstable. As an example, in Figure 7 it can be seen how a species by a slight alteration of a CS a new favorable species may be produced. For instance Species 19 — Moving, if changing CS 11-5 Continuous: Operators walk with in-line cart to CS 11-6 Continuous: Operators “slide” past others, this produces Species 20 — Sliding station.

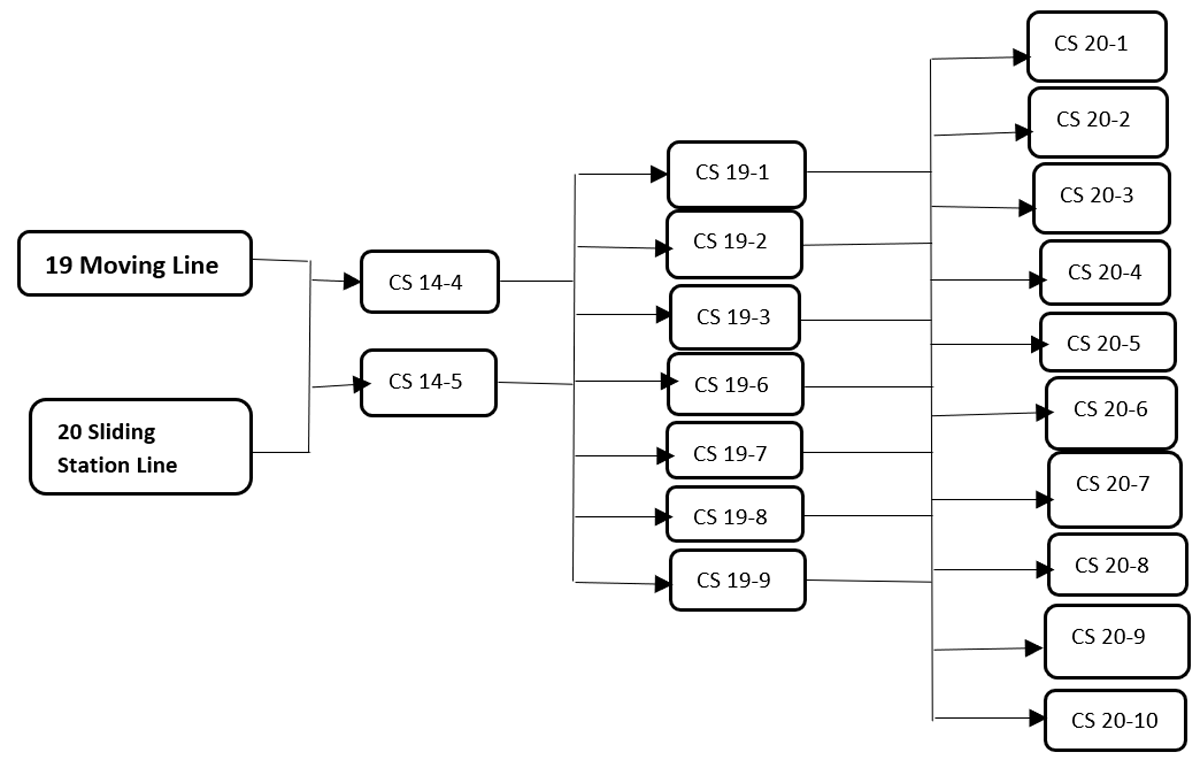

The great potential varieties of these two species is favorable as it gives the manufacturing industry more freedom to select from. This is shown in Figure 8 through the different combinations of CSs of Specific Order Type, Product Line Layout and Product Line Configuration, the CSs relevant for these two Species. They both have the potential of CS choice between the Variety-Defining CSs 14-4 to 20-10 for developing their new Varieties.

Figure 8

Figure 9

Both the machine Paced Moving Line (Species 19) and the Machine Paced Sliding Line (Species 25) also have a continuous PHMS but whereas with the former the operators perform process(es) by ‘walking/moving) with in-line cart (CS 11-5), the latter has some workstations that ‘slide’ past other workstations to perform process(es) (CS 11-6).

As can be seen from Figure 8, there are a possible 140 Varieties each of the Machine Paced Moving Line and Sliding Station Line with potential combinations of the Variety-Defining characters of Specific Order Type (primarily either assemble/configure-to-order (CS 14-4) or assemble-to-stock (CS 14-5); Product Line Layout (primarily either space constrained (CS 19-1); line (CS 19-2); Y-shape (CS 19-3); segment-L (CS 19-6); segmented-U (CS 19-7); rectangle (CS 19-8); or loop (CS 19-9); and Product Line Configuration (primarily either standalone line (CS 20-1); parallel line (CS 20-2); sub-cell line (CS 20-3); multi-sub-cell line (CS 20-4); sub-line line (CS 20-5); multi-sub-line line (CS 20-6); parallel sub-cell line (CS 20-7); parallel multi-sub-cell line (CS 20-8); parallel sub-line line (CS 20-9); or, parallel multi-sub-line line (CS 20-10).

Intervention into a system to trigger instability and applications for change

The gap between the present manufacturing performance of a firm and how it wishes to perform has to be addressed focusing on three things (Slack et al, 2006); a) assess the current performance characteristics, b) derive a set of target levels of performance, and c) compare the present against the target performance. The methodological approach will involve the comparison between many characteristics of the “self-injurious” variant specimen and the ideal species. Human intervention could trigger the instability by changing character states The idea being to subject it to an intervention and that intervention will make it an ideal species in formation. The ideal species is taken as the theoretical model for change. The comparison between the ideal species model and the variant of the species, the specimen in need of change will indicate what actions need to be taken. It is when this classification system has been used as an expert system and diagnostic tool where manufacturing firms can reflect on the system model that strategy evolves. In other words new actions for change can be taken. As these firms learn from their actions they can really start to change their systems. In other words what will function for the firm will create, for example, a new layout form.

The intervention into a complex system is about creating coherent fluctuations for more predictable results. In Darwinian terms the intervention is about achieving more rapid changes and select for different characteristics than nature would have done. The higher degree of variability is very favorable as it gives the environment more freedom to select from. The potential high degree of variability as illustrated in Figure 8 is an example of this.

Through time and space the world environment has selected numerous species that can be successfully sustained in specific environments, and give more predictable results. Figures 6 and 7 describes the more significant of these species as they have appeared in text books of manufacturing species. In practice these are the species that a company can choose from in order to improve their manufacturing systems. The text-book species is only the preliminary stage of a human intervention for change starting at the level of the hierarchical and cladistics classification. The real is defined by the present identity and also by the result after exploring and implementing a new species or variety of species.

In practice a company must a) Forecast the size of future demand and trends for the organizations products, b) Identify markets to be served, c) Assess the strength and weaknesses of the organization both absolutely and relative to its competitors (Crouch & Housden, 2003). This means that the company has to identify where they are in the classification. Then they must search out which species or variants of species are relevant for satisfying where they want to be.

The classifications can be used to reveal the change process that connects the development processes and technologies, to their overarching manufacturing system, and can be used as a benchmarking tool that enable users to view manufacturing systems in an evolutionary landscape, gauge performance, and identify strategies and tools for improvement.

The cladistics classification not only sheds light on the possible origin of manufacturing and its historical development, but also offers a tool to both compare and contrast similarities and dissimilarities, and gauge the “distance” and relative difficulty of change required to transform from one system to another. Relationships between manufacturing systems are evident not just at the manufacturing system level with the cladistics, but also at the genus, family and order levels when referring to the hierarchical classification. The promise of the “blueprint” or “recipe” for a manufacturing system, which to benchmark is now much more evident.

References

Allen, P.M. (1997). Cities and Regions as Self-Organizing Systems: Models of Complexity, ISBN 9789056990718.

Allen, P.M. (2001). "A complex system approach to learning in adaptive networks," International Journal of Innovation Management, ISSN 1363-9196, 5(2).

Allen, P.M., Strathern, M., and Baldwin, J.S. (2006). "Evolutionary Drive: New understanding of changes in socio-economic systems," Emergence: Complexity & Organization, ISSN 1521-3220, 8(2): 2-9.

Belgaev, D.K. (1979). "Destabilizing selection as a factor in domestication," Journal of Heredity, ISSN 0022-1513, 70(5): 301-308.

Crouch, S., and Housden, M. (2003). Marketing Research for Managers, ISBN 9780750654531.

Darwin, C. (1859). The Origin of Species, ISBN 9780192834386.

Dawkins, R. (1989). The Selfish Gene, ISBN 9780198788607.

Haas, J. and Johnson, N. (1966). "Toward an empirical derived taxonomy of organizations," in R. Bovers (ed.), Studies on Behavior in Organization, University of Georgia Press, Athens, GA, pp. 157-180.

Hennig, W. (1966). Phylogenetic Systematics, ISBN 9780252068140.

Leseure, M.J. (2000). "Manufacturing strategies in the hand-tool industry," International Journal of Operations & Production Management, ISSN 0144-3577, 20(12): 1475-1487.

Linnaeus, C. (1958). Systema Naturea, ISBN 9781248143360.

Lockey, J. (1966). The Thermodynamics of Fluids, ISBN 9780435717049.

Prigogine, I. (1978). Time, Structure and Fluctuations, Science, ISSN 0036-8075, 201(4358): 777-785.

Prigogine, I., Nicolis, G., and Babyloyantz, A. (1972). "Thermodynamics of Evolution (Part II)," Physics Today, ISSN 0031-9228, 25(11): 38-44.

Rose-Anderssen, C. (1994). Complexity, 50 x 70 cm painting acryl on paper.

Rose-Anderssen, C., Allen, P.M., Tsinopolous, C., and McCarthy, I. (2005). "Innovation in Manufacturing as an evolutionary complex system." Technovation, ISSN 0166-4972, 25(10): 1093-1105.

Rose-Anderssen, C., Baldwin, J., and Ridgway, K. (2016). "A cladistics and Linnaean exploration into the Darwinian selection of favorable varieties of the ideal / textbook manufacturing species," Emergence: Complexity & Organization, ISSN 1521-3250, 18(2): 90-118.

Rose-Anderssen, C., Baldwin, J., and Ridgway, K. (2017). "Manufacturing systematics and cladistics: State of the art and generic classification," Journal of Manufacturing Technology Management, ISSN 1741-03X, 28(5): 655-685.

Slack, N., Chambers, S., Johnston, R., and Bates, A. (2006). Operations and Process Management-Principle and Practices for Strategic Impact, ISBN 9780273684268.

Uvarov, E.B., Chapman, D.R., and Isaacs, A. (1964). A Dictionary of Science, ISBN 9780140510010.